Portrait of Alexander Hupfer, Head of Production at FRIKE

“Hardly any product off the shelf”

For a customer from Germany, we are combining their existing cone cart with a FRIKE Rumble Strip Handling Machine. At FRIKE, Production Manager Alexander Hupfer is the central coordinator for this custom-made project.

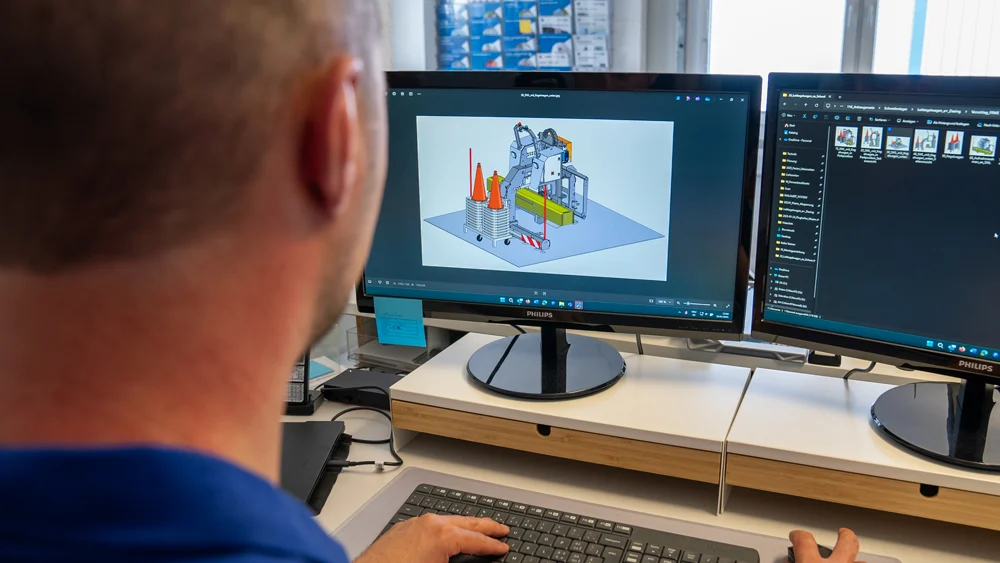

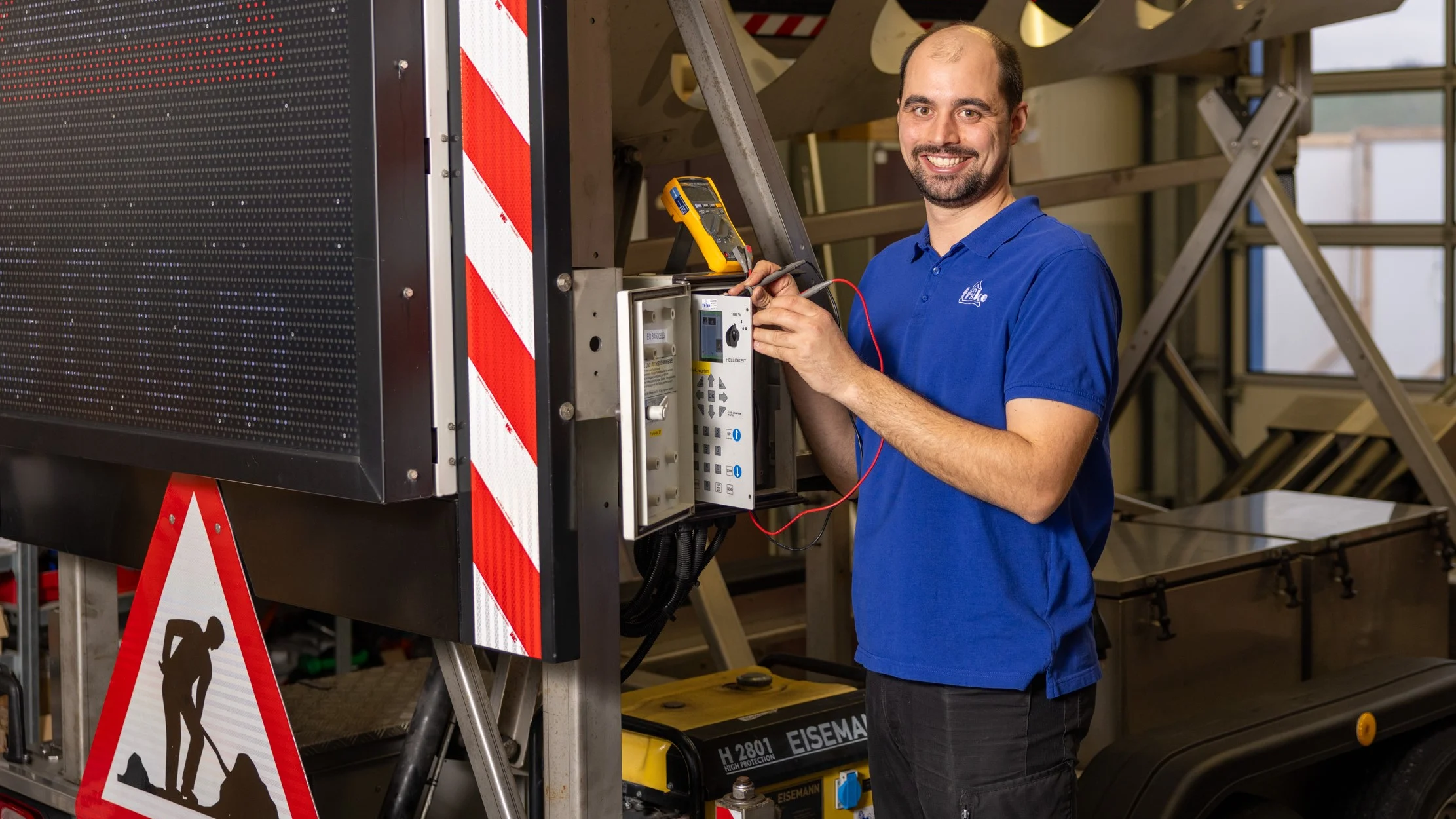

Alexander Hupfer, Production Manager at FRIKE, looks intently at his computer, studying a CAD drawing of a Rumble Strip Handling Machine. It’s a custom-made project for a customer from Germany. “The customer would like to purchase our attachment but still wants to continue using their cone cart at the front of the vehicle,” the 32-year-old explains matter-of-factly. Together with his team colleagues, he has sketched ideas, assessed feasibility, and developed a technical concept. The focus: the customer’s needs. “We always try to present the customer with various options and closely involve them in the development process,” says Hupfer. He acts as the link between technical implementation and the client’s wishes. Hupfer: “I’m an idea generator, technical point of contact, coordinator, and translator of complex issues.” In short: all the threads come together with the production manager.

Modifications and custom fabrications

Three years ago, the calm Hohentengen native, who often helps out on the family farm after work, joined FRIKE. “I enjoy the variety in my job – sometimes working at the computer, sometimes in the workshop, or directly with the customer,” he says. Another advantage is that, due to the company’s size, every customer can be individually addressed. In addition to selling the standard product range, Alexander Hupfer’s team modifies existing products daily or manufactures completely custom solutions to meet customer requests: “The trend towards autonomous solar solutions means that we hardly sell any off-the-shelf products.” Recently, 200 self-developed and produced StopLane - Airport Barricade Hazard Light were shipped to Munich Airport. “It’s a special feeling to know that the products you have designed and assembled are in use worldwide,” he proudly explains.

Balancing act between functionality and cost

The Rumble Strip Handling Machine combined with the cone cart will soon ensure safety on German highways. However, before it reaches the roads, the special design will undergo various stress tests. “For custom-made products, we always strive to maximize functionality while staying within budget. In other words: a special product must be cost-effective — for us and for the customer. That is a FRIKE principle,” says the trained mechanic and mechanical engineer. This is another exciting challenge in his daily work.

"I can always count on my team 100%.""

Alexander Hupfer, Head of Production

Hand in hand

Bei der täglichen Arbeit kann er sich auf sein Team verlassen. Unsere langjährigen Produktionsmitarbeitenden beherrschen die Handgriffe aus dem Effeff und unterstützen den Produktionsleiter insbesondere in der Fertigung und Montage: «Ich kann immer zu 100% auf mein Team zählen – das schätze ich sehr.» Aufgrund der Zunahme individueller Kundenwünsche baut Alexander Hupfer in seinem Team weiteres Fachwissen auf: «In Kürze wird uns ein zusätzlicher Mechaniker verstärken, der mich bei der Anfertigung von Spezialkonstruktionen unterstützt und Reparaturen beim Kunden selbstständig abwickeln wird.» Denn: Arbeit gibt es bei FRIKE genügend.

Are you looking for a custom product solution tailored to your needs?

We would be happy to advise you personally.